six sigma and lean Six Sigma are powerful, data-driven methodologies for process improvement. Aiming for high quality and efficiency by minimizing defects, these methods have transformed countless organizations. Six Sigma certification, especially the Black Belt level, equips professionals to lead change projects using structured approaches like DMAIC (Define, Measure, Analyze, Improve, Control). Adhering to Lean Six Sigma principles offers enhanced customer satisfaction, reduced costs, and a competitive edge. Real-world applications range from manufacturing to healthcare, with proven success stories of defect reduction, improved efficiency, and better outcomes. Comprehensive Six Sigma training, available in New Britain, CT, empowers employees at all levels to drive continuous improvement across various industries.

“Discover the transformative power of Lean Six Sigma, a powerful combination of Lean and Six Sigma methodologies for process optimization. This article explores how New Britain, CT, can leverage these tools to enhance efficiency and reduce waste. We’ll delve into the fundamentals of Six Sigma, its synergistic approach with Lean, and the tangible benefits it offers local businesses. Additionally, we’ll guide you through the path to becoming a Six Sigma Black Belt and share real-world success stories from certified professionals.”

- Understanding Six Sigma: A Comprehensive Overview

- Lean Six Sigma: The Synergistic Approach to Process Improvement

- Benefits of Implementing Lean Six Sigma in New Britain, CT

- Becoming a Six Sigma Black Belt: Skills and Training Required

- Real-World Applications: Success Stories from Six Sigma Certification Holders

Understanding Six Sigma: A Comprehensive Overview

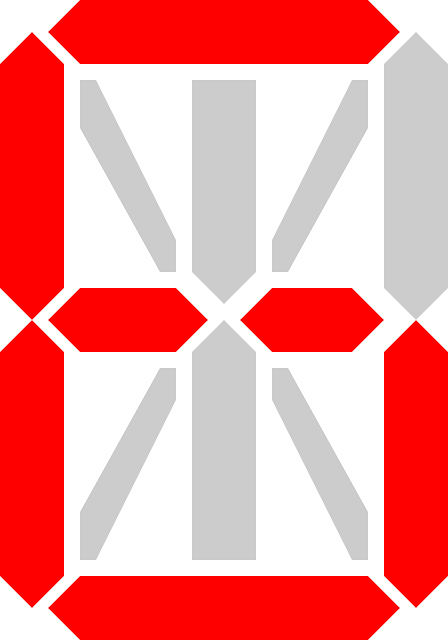

Six Sigma is a powerful data-driven process improvement methodology that aims to enhance quality and efficiency. At its core, Six Sigma focuses on reducing defects and variations in processes, ultimately striving for near-perfect performance. This method involves a structured approach, utilizing statistical tools and techniques to identify and eliminate root causes of problems. The term ‘Six Sigma’ refers to the goal of achieving no more than 3.4 defects per million opportunities, ensuring an extremely high level of quality.

This methodology is widely recognized for its ability to bring about significant changes in organizations. Six Sigma certification, such as the well-known Six Sigma Black Belt, empowers professionals to lead and implement these improvement projects. The process involves defining and understanding the current state, designing and implementing solutions, and then monitoring and controlling the new improved processes. By adhering to the lean six sigma principles, organizations can achieve remarkable results, enhance customer satisfaction, and gain a competitive edge in the market.

Lean Six Sigma: The Synergistic Approach to Process Improvement

Lean Six Sigma represents a powerful synergistic approach to process improvement, combining the best practices of Lean and Six Sigma methodologies. By fusing these two efficiency-focused philosophies, organizations like New Britain CT can achieve remarkable results in streamlining operations and enhancing overall performance. This combined method not only identifies and eliminates waste but also drives out variability, leading to improved quality, faster cycle times, and reduced costs.

At its core, Lean Six Sigma emphasizes data-driven decision making and a structured problem-solving process known as DMAIC (Define, Measure, Analyze, Improve, Control). Individuals trained in Six Sigma, including Six Sigma Black Belts, play a crucial role in driving these improvements by facilitating teams through the methodology. This includes obtaining six sigma certification to ensure proficiency in applying statistical tools and techniques for analyzing data and implementing effective process changes. Ultimately, Lean Six Sigma training equips professionals with the skills needed to deliver measurable results that drive business growth and competitive advantage.

Benefits of Implementing Lean Six Sigma in New Britain, CT

Implementing Lean Six Sigma in New Britain, CT offers a multitude of benefits that can significantly transform local businesses and industries. By combining the principles of Lean, focusing on waste reduction and process efficiency, with Six Sigma’s data-driven approach to eliminate defects, organizations can achieve remarkable improvements in quality, speed, and cost-effectiveness. This hybrid methodology is particularly powerful in manufacturing, healthcare, and service sectors, where continuous improvement is key to staying competitive and meeting customer demands.

New Britain businesses that embrace Lean Six Sigma can expect enhanced operational efficiency, leading to increased productivity and reduced costs. The structured approach of Six Sigma certification, from Yellow Belt to Black Belt levels, empowers employees at all levels to identify and resolve issues, fostering a culture of continuous improvement. Accessing six sigma training and certifying through recognized programs ensures that practitioners employ the latest tools and techniques, making New Britain a hub for modern process optimization. This strategic shift can drive economic growth, attract new businesses, and solidify the region’s position as an example of successful industrial revolution in today’s digital era.

Becoming a Six Sigma Black Belt: Skills and Training Required

Real-World Applications: Success Stories from Six Sigma Certification Holders

The real-world applications of Six Sigma are vast and varied, with countless success stories from individuals and organizations who have embraced this methodology. Those who have obtained Six Sigma certification, especially at advanced levels like Six Sigma Black Belt, often lead projects that drive significant improvements in efficiency and quality. For instance, manufacturers have used Six Sigma to reduce defects by over 80%, leading to increased customer satisfaction and substantial cost savings. Healthcare institutions have employed the principles of Six Sigma to streamline procedures, reducing wait times and improving patient outcomes.

These success stories aren’t limited to large corporations; small businesses and public sector organizations also benefit from Six Sigma training. By focusing on data-driven decision-making and continuous improvement, Lean Six Sigma principles empower teams to tackle complex problems and achieve remarkable results. This methodology’s flexibility allows for its application across various industries, making it a valuable tool for anyone looking to optimize processes and deliver exceptional value.

Lean Six Sigma emerges as a powerful methodology for process optimization in New Britain, CT. By combining the efficiency of Lean and the precision of Six Sigma, organizations can achieve significant improvements in quality, speed, and cost reduction. The article has explored the fundamentals of Six Sigma, its synergistic approach with Lean, benefits for local businesses, and the path to becoming a Six Sigma Black Belt. Embracing Six Sigma training and certification can unlock transformative potential for any organization looking to excel in process improvement and gain a competitive edge.